Leading brand of LED SMT machine

Focus on SMT equipment for 15 years

Consultation hotline

Leading brand of LED SMT machine

Focus on SMT equipment for 15 years

Consultation hotline

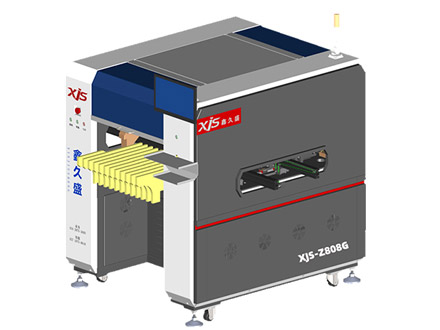

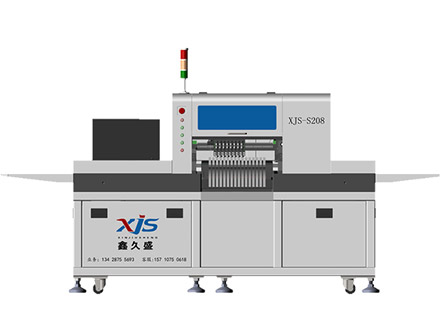

High speed up and down vision 8-head LED copper wire lamp placement machine

Model:XJS-S208A

1、 Product Introduction

The XJS-208A adopts the design concept of precision screw, linear guide, and servo imported from Japan, equipped with MARK point positioning visual function and component recognition camera. Pursuing high-speed completion of SMT while fully ensuring the stability of equipment high-speed operation, it is an excellent cost-effective LED copper wire light string SMT machine.

Xinjiusheng provides customers with copper wire light string production equipment, processes, and equipment support throughout the entire process. Our company can provide customers with copper wire light winding machines, copper wire light crimping machines, copper wire light film pulling machines, copper wire light film release machines, copper wire light solder paste printing machines, copper wire light polishing machines, copper wire light placement machines, copper wire light reflow soldering, copper wire light ovens, copper wire light dispensing machines, mold strips, and all other equipment and accessories. We offer on-site training on production processes, including teaching!

2、 Product images

3、 Functional Features

1. The X-axis, Y-axis, and feeding platform all use high-precision imported precision screw rods to improve equipment operation accuracy and transmission speed;

2. MARK visual correction system takes photos and recognizes the position of PCB boards to ensure the accuracy of surface mounting.

3. The Z-axis of the sticker head adopts 8 sets of imported splines, which efficiently completes LED material picking and discharging;

4. Powerful function: Equipped with different feeders, it can meet the installation requirements of various LED products.

5. Easy to operate: Chinese graphical user interface, easy to operate. Programming is concise, capable of storing and editing files, and can be easily accessed;

6. Easy to maintain: The design is simple and easy to maintain. The cost of replacing parts is low, and the maintenance cost is also low.

7. The software, circuit, and hardware structure of the entire machine are independently developed by our company and have independent intellectual property rights.

4、 Application scope

LED copper wire light string

5、 Reference configuration

1. Control system: industrial computer+precision motion control card+branded LCD display

2. Software system: Xinjiusheng independently developed Chinese operating system

3. Sports motor: Original Panasonic motor from Japan

4. Adhesive suction nozzle: independently developed multiple models of suction nozzles

5. Sliding device: precision screw+linear guide rail

6. Visual device: upper MARK point recognition+lower component recognition

7. Feeder: Using Yamaha Pneumatic Fit from Japan

6、 Technical parameters

| Technical Parameter | |

| Equipment model | XJS-S208A |

| Maximum circuit board area | 1500(X)╳350(Y)╳25(Z)mm |

| Maximum Z-axis movement range | 20mm |

| Maximum movement range of PCB slide table | 1300mm |

| Maximum SMT speed | 32000CPH |

| Average SMT speed | 25000-32000CPH |

| positioning accuracy | 0.05mm |

| Suction nozzle buffer range | 4.0 |

| power supply | 220V, 50Hz |

| control mode | pc computer |

| compressed air | 0.65-0.75Mpa |

| Average power | 800W |

| band feeder | 8. 12, 16, 24mm Feida |

| scope of application | Resistive and capacitive components above 0603, as well as various LED chips such as 2835, 3528, 3014, 4014, 5050, 5630, 5730, 7070, etc., are compatible with various high-power chip mounting |

| Number of feeders that can be placed | 16 |

| Using motors | Panasonic AC servo motor |

| heads | 8 heads |

| Motion Drive System | Advanced Communication Servo System |

| Component angle | 0-360 ° arbitrary angle, synchronous rotation during motion |

| X/Y operating mode | New generation linear interpolation linkage self-developed software |

| Gas source | Imported vacuum pump |

| operating system | Xinjiusheng independently developed |

| Programming method | Point to point teaching of programming, visual programming, can be optimized |

| Product weight | 1500KG |

| outline dimension | 2100mm *1200mm *1400mm |

版权所有 © 2014-2025 深圳市新久盛自动化设备有限公司

Scan to consult customer service

Scan to consult customer service